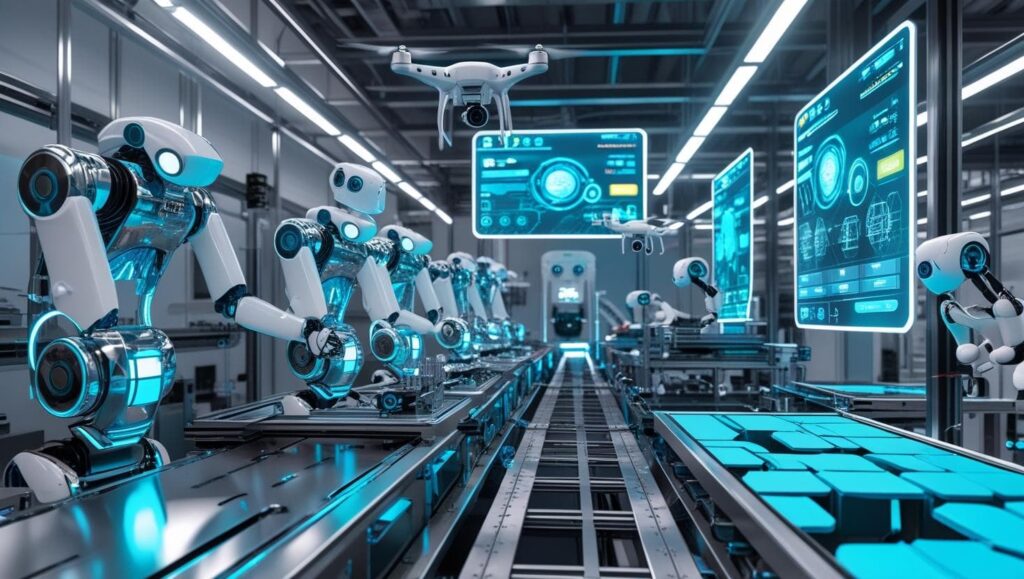

AI, or Artificial Intelligence, is a computer system that can think, learn, and make decisions on its own. It looks at data, spots trends, and gives smart suggestions. In manufacturing, AI doesn’t just work, it thinks. It checks how machines run, keeps workers safe, saves energy, and tracks what customers want. It also helps improve the way factories run.

It’s like giving your factory a brain that never sleeps.

So when we ask for AI use cases in manufacturing, we’re really asking: How do factories use smart tools to get better every day?

AI is a computing system that trains itself on data, and is capable enough to make decisions on its own, without needing a human. It can explore data, recognize patterns, and present smart recommendations.

In factories, AI doesn’t just do jobs, it also thinks. It watches how machines work, makes sure workers are safe, keeps an eye on energy use, and sees what customers need. This helps factories run more smoothly and save time and resources.

The use of AI in manufacturing is taking place in many aspects of the factory. There are so many areas in which AI is making a considerable impact, not just in regular cases.

Let us explore two areas below:

Once you hire someone to work in a factory, you’ll need to teach them how to use the machines. Learning how today’s machines work can take time. With advanced AI technology, we can utilize virtual simulations, tutorials, and digital assistants to provide step-by-step instructions on tasks.

Additionally, AI is helping to determine how well operators have learned and to identify some recommendations to improve their instructions.

It increases significantly:

AI doesn’t only help machines, it helps people as well. Factory managers in this kind of workplace spend almost every day deciding things like buying more raw materials, getting the most out of their machines, or planning work shifts for their teams. With AI, we can analyze all of the past data and provide AI insights and recommendations for the factory manager daily. This ensures that time and money are saved.

Think of using AI in manufacturing like a digital assistant that helps your team leaders and plant supervisors.

At times, a factory will produce more product than necessary, and other times, products will sell out before a need can be fulfilled. AI can track real-time orders, inventory, past orders, seasonal changes, and even consumer reviews to forecast the next desired product accurately.

This process, known as demand forecasting, will prevent:

AI can monitor not only the machines in a factory but also human behaviour. Smart sensors can pick up on undesirable behaviours by the workers, such as standing too close to a hot surface or bending incorrectly to lift a heavy item. AI provides a gentle warning to remind the worker to properly follow work processes safely.

In short, AI can act like a safety coach that’s always on the job and never rests.

Artificial intelligence (AI) can manage the air, lighting, and temperature in large plant factories. If AI sees that there is excessive heating in one corner or a lack of sufficient air in another corner, it can either adjust fan speeds or airflow through vents all by itself. This instant adjustment keeps workers more comfortable and potentially keeps machinery from overheating, which is a huge feature. It can serve as an intelligent building control system for industry.

Growing numbers of factories are becoming more automated. It is not unusual for factories to have multiple (and sometimes a dozen) machines operating together in a collaborative manner (like a team!). When automation occurs through a series of machines like this, it is tough for all the machines to communicate effectively. Every machine/subsystem wants a clear directive. AI will act as the translator between machines as well as the planner between machines. AI will communicate to each machine what tasks to complete, how long to wait, and what speed to operate at. So, each machine is always working in coordination, and there is no confusion. This gives us the foundation of a “connected factory”.

Let’s check out how real companies are answering the question: “How is artificial intelligence used in manufacturing?” Here are recent examples from companies across the globe.

At Haier (a popular home appliances manufacturer), factory workers now have AI-powered smart glasses to guide them through troublesome tasks. The smart glasses provide tips on the display while workers build parts. It’s like having a helper there whispering instructions without speaking.

Toyota is using AI to watch the body and hand movements of factory workers. If a worker moves in a way that can cause injury, the AI system gives a gentle alert. Toyota’s accident rate has decreased significantly by implementing AI in this way.

Nike uses AI to track people’s purchasing habits in stores or online searches. AI updates Nike’s production plans based on the latest fashion trends and recent purchases. AI helps Nike stay fresh and new without overproducing.

ABB operates as a single operating entity with different robotic models (many with AI). The AI detects changes made by one robot and decides how robots operating in the same space need to change speed or not. Crashes don’t happen. Confusions are avoided.

These companies show that AI isn’t just for fun. It can be a useful tool for making factories work smarter.

You don’t have to spend a lot of money to use artificial intelligence. You can start small if you are focused.

At WebOsmotic, we want to help factories use AI without feeling confused or overwhelmed. Whether you run a textile factory, an electronics line, or a metal workshop, our mission is to build AI tools that match your needs.

We will partner with your team to:

We don’t think one solution works for everyone. Your factory isn’t like any other, so your AI tools should be made just for you.

If you are ready to have a conversation about the use of AI in the manufacturing sector, let’s connect. It starts and can continue with one meeting.

We learnt about AI in manufacturing use cases and much more. AI is not only about machines. It is about enabling human workers to be more productive and keeping factories safe. AI helps scale businesses with new efficiency gains, without wasting time or resources.

In our day-to-day life, AI is already working alongside people. It will eventually enable factories to explore new dimensions regarding creativity and innovation, in a way that is gentle and more sustainable for the Earth.

When we think about how AI is used in manufacturing, it can train workers, forecast trends, reduce errors, conserve energy, and allow every aspect of a factory to speak to each other. And that’s just the beginning!

If your factory is ready to modernize, AI may just be the partner you’ve been hoping for! Contact WebOsmotic to know the intricacies, and discuss how you can save money on deve,opening your next AI model.