AI has become the driving force behind some of the most sophisticated logistics operations globally. The once-in-a-lifetime question is how storm rerouting deliveries are accomplished at the ease of a click, there is always AI lying behind the curtain. While digging into the world of possibilities one thing stands clear, logic isn’t just impressive it’s downright shocking.

One of the most real and easy-to-understand examples of AI in logistics is smart systems that work on their own. These systems can change truck routes to avoid traffic without human help. Robots can place and pick items in warehouses by themselves. AI can even tell if a delivery truck may break down days before it happens. All of this does not happen only in labs. It is already used in real work all over the world.

Time to explore those out of the box phenomena tales of AI being used to solve logistic problems in an unimagined way.

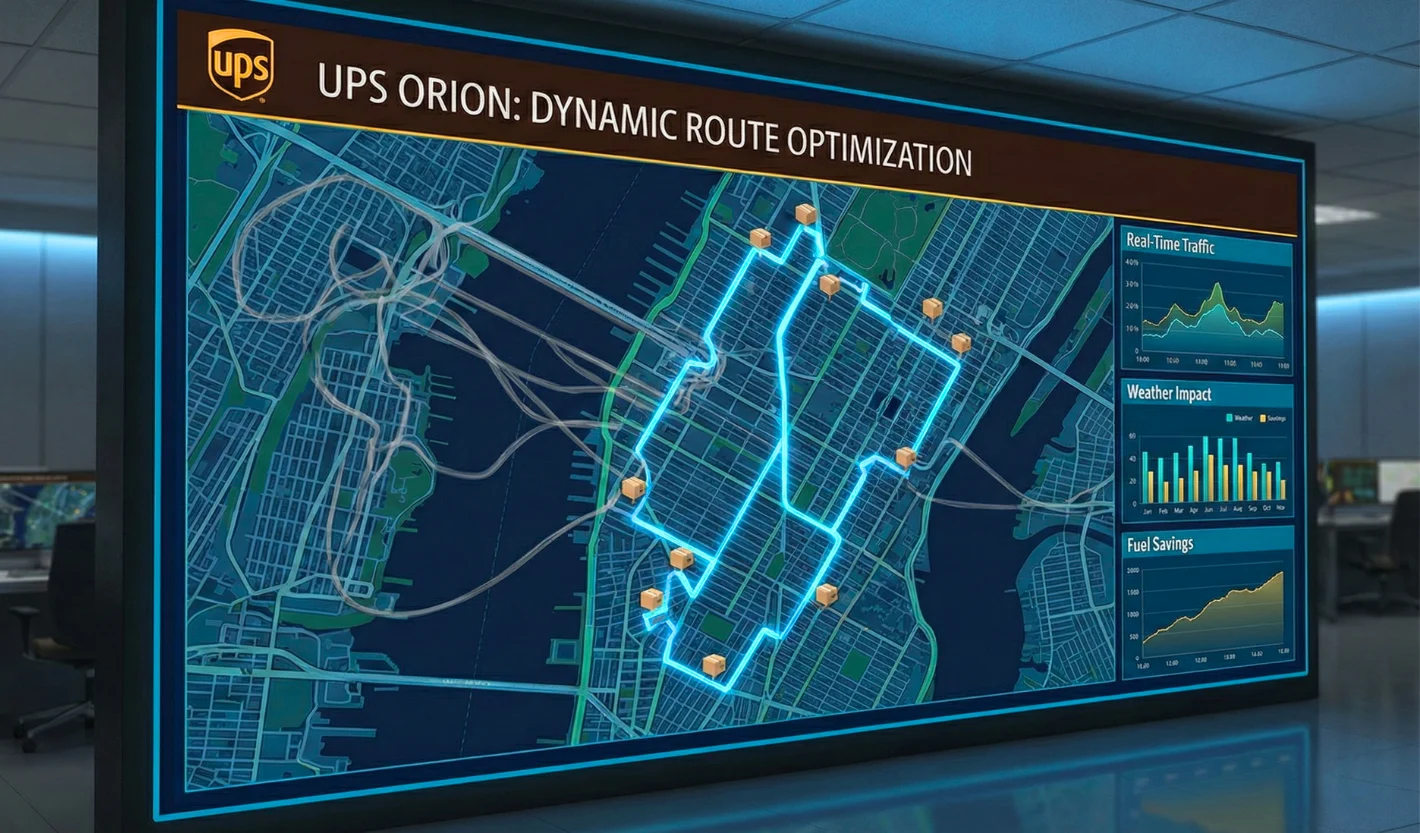

Let us move to one of the most known and still astonishing AI in logistics examples that is UPS ORION (On-Road Integrated Optimization and Navigation).

The system uses AI to determine the most effective routes for drivers using over 250 million address points a day. Each route is tailored using a comprehensive analysis of traffic conditions, weather patterns, customer options, and even the size of the packages to be delivered. ORION optimizes driving and fuel consumption so astonishingly that it saves UPS annually over 100 million miles and 10 million gallons in fuel.

This accomplishment is impressive to say the least, and serves as a milestone for innovations in logistics. The next time a UPS package arrives a day early, you know who to owe thanks to: the AI.

Perhaps an even more astonishing example of AI in logistics is the integration of robotics and AI to Amazon’s warehouses. With the inclusion of AI systems, the mobile bots and robotic arms are capable of:

The fulfillment of orders has been reduced significantly. For some clients, requests are fulfilled in under fifteen minutes. This makes Amazon one of the leading corporations in the application of AI technology in logistics.

AI is being used innovatively by DHL, one of the largest logistics operators, in the field of Vision Picking. Not only do they equip warehouse workers with smart glasses, but AI also supports these glasses to illustrate a picking list in real time right in front of their eyes.

These complete “vision picking” systems assist workers in real-time, optimizing accuracy, and productivity has increased by 25% or more. It integrates computer vision, machine learning, and augmented reality into a hands-free, state-of-the-art logistics approach.

This is a question that turns heads when asked; what is an example of AI in logistics?

China’s largest eCommerce platform JD.com has fleets of AI powered autonomous delivery robots. These robots can navigate sidewalks, avoid pedestrians, and deliver parcels right to the door of customers in urban residential areas.

Can you believe that these robots do not just follow a GPS? They utilize obstacle avoidance AI and facial recognition to confirm the specific recipient. This is not a test project, this is part of the daily delivery routines in several cities.

Aside from the implementation of AI in logistics, this may seem like science-fiction but it is a current occurrence. Just imagine how great customer experience could be with something like that!

The application of AI in logistics and supply chain is not solely about speed. It also deals with security. For example, FedEx uses an AI and IoT system for real time tracking of packages that contain sensitive items such as vaccines or lab samples.

It tracks real-time:

If any condition changes, the AI notifies the logistics team for intervention, which is critical in pharma, biotech, and electronics industries.

The world’s shipping leader, Maersk operates a central AI control tower that scans the world for shipments and ships with their thousands of cargo containers on transit.

The AI analyzes:

Thanks to this Maersk is able to steer their shipments in advance and notify of expectations to clients ahead of schedule, and in turn offering them more accurate real-time updates. When looking for examples of AI in logistics, this is one of the most powerful and enterprise-grade systems in the world.

IBM Watson has teamed up with Michelin to advance fleet management with AI. Their system tracks data on the drivers, the vehicle and its condition, and the road in real time. AI models provide recommendations to:

This application of transport AI particularly stands out in its dual achievement of boosting performance and sustainability, sorely needed by any logistics firm trying to go green.

XPO implements AI for the management of truckload deliveries throughout North America. Their machine learning technology predicts load demand and driver availability, optimizing trip planning based on:

By reducing deadhead miles and idling, costs and carbon emissions are significantly cut. This serves as one of the most remarkable examples of AI in logistics for freight and trucking.

One of the largest third-party logistics companies globally, C.H. Robinson, relies on AI for their smart Navisphere logistics platform. This tool provides real-time visibility into the supply chain, alongside predictive analytics to:

During unanticipated disruptions, supply chains continue serving customers all thanks to this innovative technology. It serves as yet another answer to what is an example of AI in logistics.

Walmart employs AI cameras at their retail stores and warehouses to keep track of inventory. These systems are able to:

This ensures minimal loss during sales as the company is able to restock seamlessly. Such a system is modern and its learning ability guarantees increased accuracy over time, showcasing machine learning at its finest.

The most surprising part? Amazon and FedEx are not the only companies with access to using AI technology. Here is how small businesses are leveraging AI in logistics:

As these examples show, robotics and AI integration within logistics is more than futuristic tech narratives. Businesses are realizing tangible benefits such as:

Cost-conscious organizations that adopt AI technologies in at least one of their logistics operations are realizing a significant competitive advantage over their peers.

Of all the cases cited above, there are underlying real-life challenges. A lot of companies are experiencing business problems related to the trustworthiness of data, information technology (IT) infrastructure, or operational accuracy, which in turn affects the quality of AI predictions. For smaller companies, the increased operational expenditure may also present an added impediment. Other difficulties include the integration of AI interfaces to archaic AI frameworks of infrastructure, machines, and systems. More so, there is a lesser abundance of personnel equipped with the requisite skills in AI and data science to operate these systems. Nevertheless, these challenges particularly are solvable with the use of the right partner and tailored blueprints, especially now that tools such as the ones related to AI are becoming more accessible and simpler to implement for varied sectors.

At WebOsmotic, we aim to get results by integrating AI into processes that matter for businesses. If the objective is to develop an automated route planner, a warehouse intelligence tool, or a delivery prediction tool, you can be guaranteed that we will help.

No more one-size-fits-all endeavors. We develop custom solutions tailored to your organizational hierarchy, primary objectives, and existing systems – the only AI in the logistics system that will align with your requirements.

AI is already to some extent present in logistics, be it through robots that pack online orders or AI predicting traffic to streamline transport activities. These examples are transforming the future of delivery and transportation.

And the best part is you don’t need to be a multi-millionaire to be part of this. With the right approach and an expert partner like WebOsmotic, adopting smarter logistics is straightforward.