Are you ready to disrupt with AI? Join our Hackathon today! Click to Register

By WebOsmotic Team | Published on September 11, 2024

Summarize Article

Table of Contents

ToggleAutomation in the manufacturing industry increases productivity by reducing manual labor, minimizing errors, and speeding up production. It uses robotics, sensors, and AI to streamline tasks like assembly, inspection, and packaging. Automated systems lower costs, improve consistency, and enable 24/7 operations.

A manufacturing automation business uses robotics, software, and control systems to improve production efficiency, reduce labor costs, and enhance quality control across various industries.

In our fast-paced contemporary world, the manufacturing sector continually strives to enhance efficiency and productivity. One groundbreaking solution that has transformed the industry is industrial automation. By harnessing cutting-edge technologies, automation has revolutionized traditional manufacturing processes, leading to heightened profitability and a competitive edge.

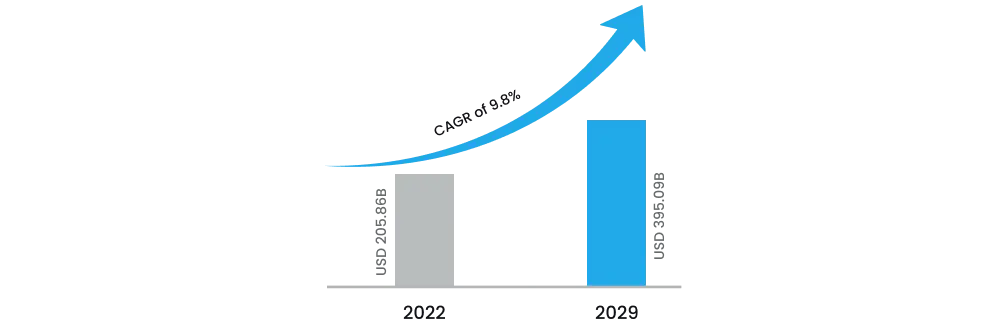

Even the report of Fortune Business Insight hints at this possibility: The global industrial automation market size is estimated to grow from USD 205.86 billion in 2022 to USD 395.09 billion by 2029, at a CAGR of 9.8% during the forecast period 2022 to 2029.

Manufacturing automation refers to the integration of sophisticated machinery, computer systems, and robotics to execute tasks that were traditionally performed by human operators. It entails the assimilation of intelligent systems that streamline and optimize the production process, thereby diminishing the necessity for manual intervention and enhancing overall efficiency.

Automation has become an indispensable component of contemporary manufacturing, with applications ranging from assembly lines and quality control to inventory management and logistics.

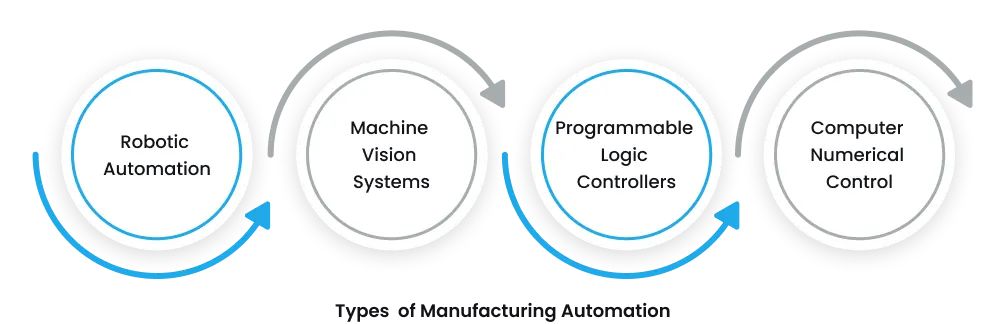

Several distinct types of manufacturing automation cater to different facets of the production process. Here are some of the most prevalent categories:

To gain a deeper understanding of the profound impact of manufacturing automation, let us examine a few real-life examples:

The implementation of automation in the manufacturing sector users in a multitude of benefits, including:

Automation offers numerous advantages across various areas of the manufacturing domain. Here are five key areas where automation simplifies processes:

By automating repetitive tasks, manufacturing companies can significantly enhance production rates while maintaining consistent quality standards. Automation reduces human error, minimizes downtime, and facilitates continuous operations.

Automated systems enable real-time tracking of inventory levels, ensuring optimal stock levels and preventing shortages or overstocking. This streamlined supply chain enhances overall operational efficiency.

Machine vision systems and sensors are crucial in industries for precise and consistent quality control. Equipped with specialized cameras and sensors, these systems detect defects and anomalies by capturing detailed images and processing them with advanced algorithms.

Automated guided vehicles (AGVs) and robotic systems efficiently handle material movement within warehouses and distribution centers. This reduces labor costs, minimizes errors, and optimizes space utilization.

Automation allows for predictive maintenance by continuously monitoring equipment performance and identifying potential issues before they lead to costly breakdowns. By scheduling maintenance based on real-time data, companies can minimize unplanned downtime and extend the lifespan of machinery.

Are you struggling to automate your business operation?

Look no further! It’s time to simplify your business process with WebOsmotic,

we provide the ultimate solution for optimizing your business workflow.

The global industrial automation market is experiencing significant growth and is poised to expand further in the coming years. Here are some key statistics and insights:

The global industrial automation market size is projected to grow from USD 205.86 billion in 2022 to USD 395.09 billion by 2029, exhibiting a remarkable CAGR of 9.8% during the forecast period of 2022 – 2029.

The market experienced a decline of 6.5% in 2020 compared to 2019 due to the impact of the COVID-19 pandemic.

The advent of 5G wireless technology and the increasing adoption of Industry 4.0 are driving the demand for automation solutions across sectors.

Partnerships and collaborations between market players are expected to accelerate the adoption of automation solutions, leveraging technologies like 5G and Industry 4.0. High initial capital investments and the fragmented nature of the industry act as restraining factors for market growth.

Software is anticipated to hold a major market share in the industrial automation sector, driven by the growing demand to streamline business processes.

Technological advancements and the emergence of Industry 4.0 are fostering innovations in industrial robots.

Europe is projected to dominate the global industrial automation market, followed closely by the Asia Pacific region. Europe boasts the highest robot density globally, while Japan is the largest producer of robots and factory automation systems.

Industrial automation has emerged as a game-changer in the manufacturing sector, propelling it toward a future that is more efficient, productive, and profitable. By leveraging cutting-edge technologies, manufacturers can streamline their processes, enhance product quality, and gain a competitive advantage.

The benefits of automation are far-reaching, encompassing improved efficiency, cost savings, and heightened customer satisfaction. Embracing automation is no longer an option but a necessity for manufacturing companies seeking to thrive in today’s highly competitive landscape.

Ready to transform your manufacturing processes with automation? Contact WebOsmotic today for a consultation and discover how our advanced automation solutions can streamline your operations, enhance productivity, and give you a competitive edge in the market. Don’t miss out on the benefits of automation – get in touch now!

Unlock exclusive insights and expert knowledge delivered straight to your inbox