Are you ready to disrupt with AI? Join our Hackathon today! Click to Register

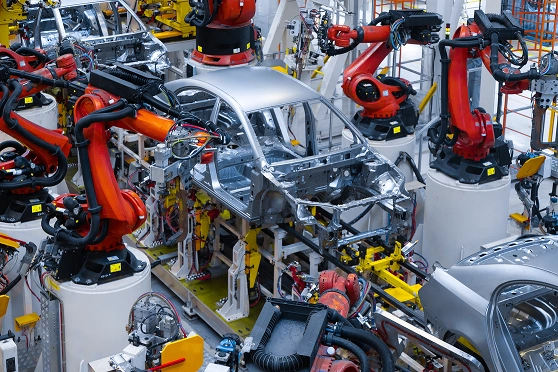

The manufacturing industry is entering a new era where efficiency, speed, and precision define success. From automotive plants to electronics factories, AI in manufacturing is reshaping how products are designed, built, and delivered. At WebOsmotic, we combine AI expertise with deep manufacturing knowledge to create solutions that optimize production lines, enhance quality control, and cut operational costs.

Our AI manufacturing solutions help you perform better predictive analytics, computer vision, and intelligent automation. This empower you with smarter decision-making and continuous process improvements. By partnering with us, manufacturers gain the tools to scale faster, innovate confidently, and stay competitive in a rapidly evolving global market.

Our AI systems analyze real-time sensor data from your equipment to detect subtle anomalies that signal impending failure. This allows you to schedule maintenance proactively, avoiding costly unplanned downtime and extending the lifespan of your critical manufacturing assets.

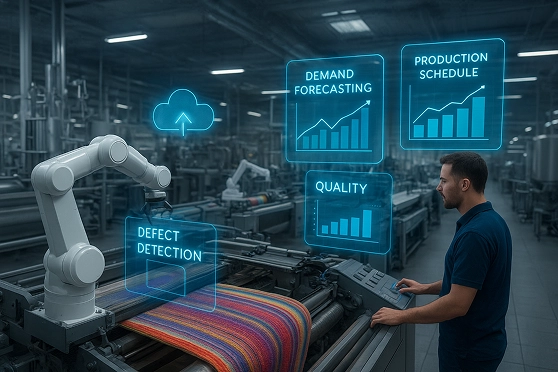

Implement high-speed computer vision systems that inspect every product on your line with superhuman accuracy. Our machine learning models are trained to identify even the smallest defects, ensuring consistent quality, minimizing material waste, and protecting your brand's reputation.

Deploy intelligent automation systems that handle repetitive, high-volume tasks with superior precision and speed. Our AI-powered solutions enable your facility to scale production efficiently while adapting quickly to changing market demands.

Gain end-to-end visibility into your supply chain with our AI intelligence platform. We provide more accurate demand forecasting, optimize logistics, and anticipate potential disruptions, helping you reduce lead times, lower transportation costs, and build a more resilient supply network.

Utilize Industrial AI to continuously monitor energy consumption across your facility in real-time. Our systems identify patterns and opportunities for optimization, reducing waste and lowering utility costs.

Our AI-powered forecasting models analyze historical data and market trends to predict material needs with remarkable accuracy. This precision helps you avoid overstocking, minimize carrying costs, and ensure you always have the right components on hand for seamless, uninterrupted production.

Our AI analytics platform uncovers deep insights into your manufacturing processes, helping you track key performance indicators, pinpoint areas for improvement, and make informed, data-driven decisions that boost overall efficiency.

We build tailored AI solutions that address manufacturing challenges such as predictive maintenance, demand forecasting, and defect detection. Our systems improve efficiency, reduce downtime, and deliver measurable impact across the entire production lifecycle.

Our AI experts work with you to identify the highest-impact use cases for manufacturing. From evaluating data readiness to building a clear adoption roadmap, we ensure your AI initiatives align with business goals and maximize ROI.

Deploy AI agents that act as digital co-workers to manage repetitive processes like inventory tracking, production scheduling, and logistics. This enables your workforce to focus on innovation and value-driven tasks.

Improve production outcomes with AI systems that detect defects in real time and predict potential failures before they occur. By combining computer vision and predictive analytics, manufacturers can reduce downtime, minimize waste, and ensure consistent product quality.

Leverage generative AI to accelerate product design and prototyping. From optimizing component structures to creating innovative blueprints, our solutions shorten development cycles and spark creativity in manufacturing design.

Turn manufacturing data into intelligence with custom ML models. From predicting equipment failures to analyzing production trends, we help manufacturers optimize operations, minimize costs, and boost overall productivity.

Selecting the right partner who understands both technology and manufacturing operations is crucial for your digital transformation. At WebOsmotic, we combine deep technical expertise with industrial know-how, delivering AI solutions that boost efficiency, quality, and innovation on the factory floor.

We build robust, scalable software tailored for manufacturing operations. From production planning systems and digital dashboards to supply chain management tools, our solutions optimize workflows, reduce downtime, and improve overall operational efficiency.

Utilizing the latest AI technologies and staying ahead of industry trends, we bring innovative custom AI training solutions to drive your business forward.

OpenAI

OpenAI Google cloud

Google cloud

Boost production efficiency and quality in automotive plants with AI-driven robotics, predictive maintenance, and defect detection. From assembly line automation to supply chain optimization, our solutions help automotive manufacturers reduce downtime and improve overall throughput.

Our solutions have helped manufacturers across industries achieve real-world results, such as:

Unlock exclusive insights and expert knowledge delivered straight to your inbox